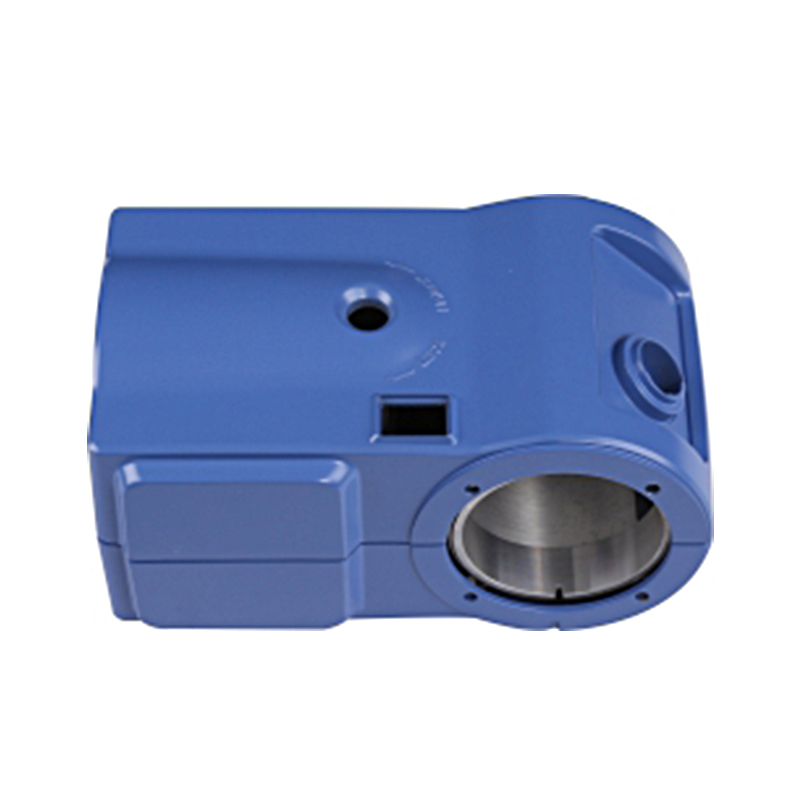

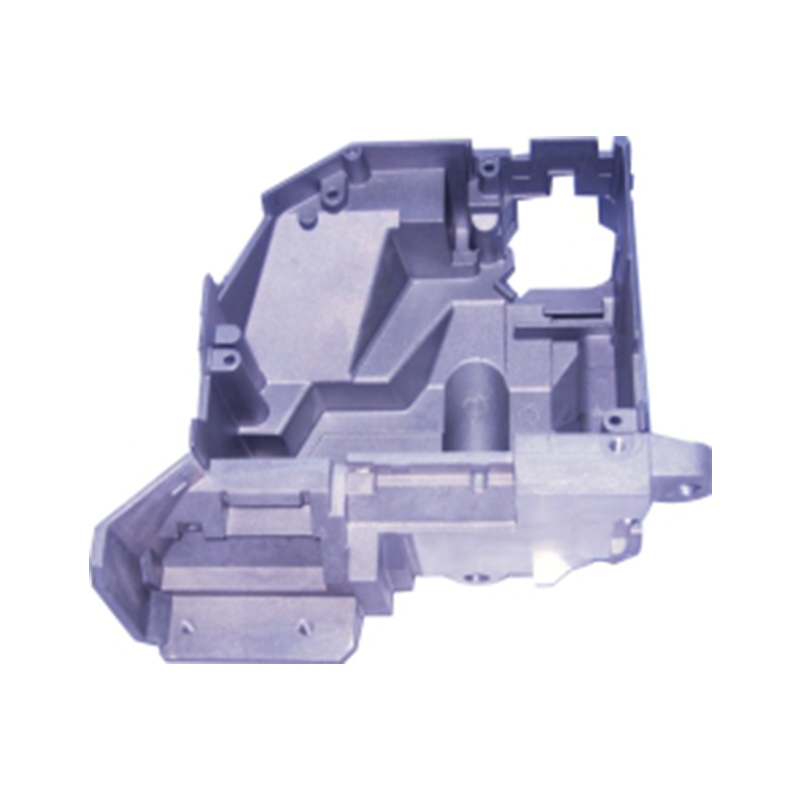

These precision components are often manufactured using die casting, and laboratory instrument die castings and molds are particularly popular due to their ability to efficiently form complex, thin-walled structures.

- +86-13662284486+86-18927456445

- CLGONG@HK-SK.COM

- No. 39, Rongfu Road, Fucheng Street, Longhua District, Shenzhen